Brewhouse

Design & Manufacture Brewhouse Is KHSP Eng & Yolong’s Passion

KHSP Eng & Yolong focus on custom making brewhouse as clients ’requirements. Brewhouse plays an important role for brewing craft beer. The situation of brewhouse directly affects taste & quality for craft beer and the daily work for brewers.

With full experiences for brewery design, KHSP Eng & Yolong has been working for automatic brewhouse for 13 years. It can much reduce brewers’ labor and have a accurate monitor on each process.

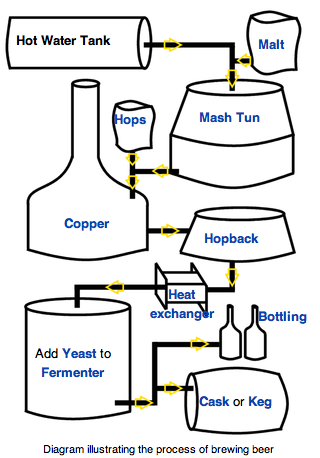

Mashing Process

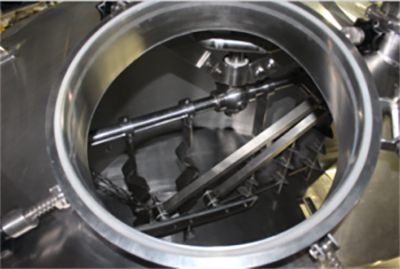

Mashing is the process to break down the starch in the grain or malt into sugar. Grain mashing processes in the Mash Mixer ( Mash Tun). The design of propellers shape in mixer is very important. KHSP Eng & Yolong technicians finalize the agitator design after constant testing. It is widely used in large brewery and microbreweries.

The advantages of KHSP Eng & Yolong agitator are:

- Mix well ( Offer opposite directions strengths inside & outside)

- High efficiency

- Mashing thoroughly

Lautering Process

Lautering is the process to separate clear wort from the mixer of grain and water. Lautering has three steps: re-circulation wort, sparging and grain out. KHSP Eng & Yolong offered two types of rake to suit for breweries, automatic up & down rake system and manual up & down scraper rake.

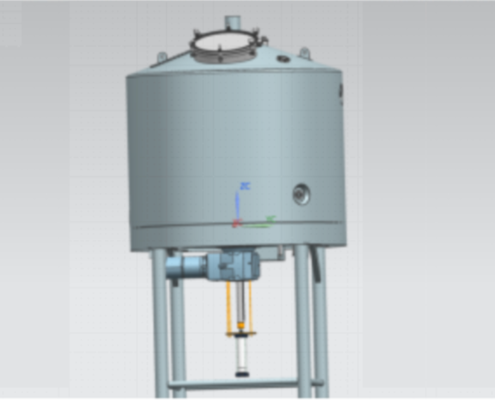

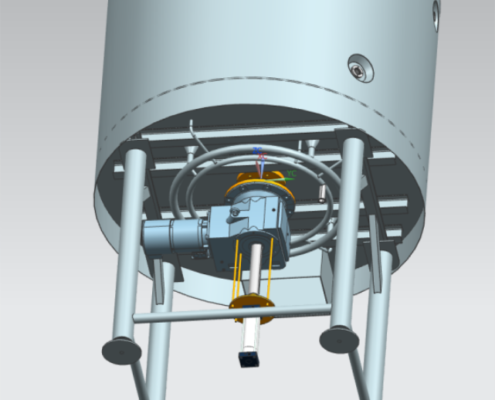

Bottom Up & Down Rake System

The Mechanical Up & Down Rake System is very popular in middle capacity breweries. It includes main arm, mechanical rakes, hook device, vertical shaft seal sleeve, vertical shaft, mechanical seal, scraper, cylinder and proximity switches that can reach full automatic control for plough & discharging grain in lauter tun.

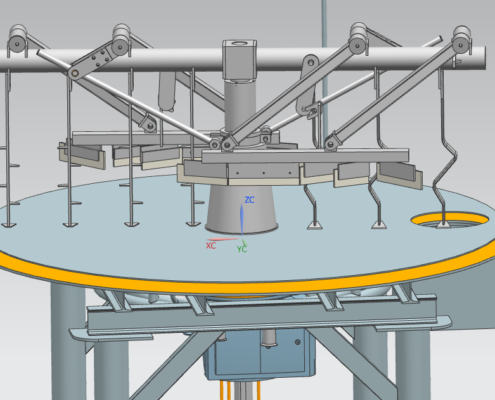

Top Mounted Rake System

Introduction:

- The rake can not up & down

- The Scraper can up & down by chain handly

- Milled False Bottom

Boiling

large capacity brewery. Generally one pump and relative piping for wort circulation are Boiling is the process to heat wort to boiling statu. Some processes will be finished during boling, some adjuncts adding, hops adding, vaporize out extra water.

Usually there are double times for adding hops, fisrt time is to break down the alpha acid in the hops and dissolve into the wort; Nearlly at the end of boiling, some brewers like to add more hops to increase the beer flavors.

The boiling is processed in Kettle, which is made of stainless steel with a function of heating. The kettle can be heated by electronic elements, steam or fire directly. It cause three kinds of design for kettle.

Steam has a relatively heating effect for wort, becasue it has a larger and dispersed heating exchange area, and the steam will not contact wort directly. Dimple jacket and calandria are common standard for steam heating kettle. The difference is

Dimple jacket standard usually works for small or middle capacity of brewpub, pilot system or breweries.

Calandrica has a high effective heat exchange rate with a higher cost, so it usually applys to needed.

KHSP Eng & Yolong engineering team worked on internal calandrica device for years and remove cirlulation pump and piping successfully. The wort circulation was processed by self-priming caused by strong wort boling in tube heat exchanger.

Additional advantage for internal & external calandrica device is avoid over-foaming during boiling.

Whirlpool

Whirlpool is a process to seperate the hot trub from wort via centrifugal force. Considering the earth rotary direction, KHSP Eng & Yolong designed the different tangential wort inlets for whirlpool tank for breweries located in Northern and southern hemispheres.

Additional KHSP Eng & Yolong makes whirlpool tun with below details for larger breweries.

- Slop Bottom for a clean discharge, without residue in tank

- Pop up spray device for better cleaning of bottom